Choosing the right Laser Engraving Machine for Metal can be overwhelming, especially if you’re new to laser technology. With multiple machine types, power options, software features, and safety requirements to consider, beginners often struggle to determine which system truly fits their needs. This comprehensive guide breaks down everything you need to know — explained simply, professionally, and based on real-world experience.

- What Is a Laser Engraving Machine for Metal?

- Why Use a Laser Engraving Machine for Metal?

- Types of Laser Engraving Machines for Metal

- How to Choose the Best Laser Engraving Machine for Metal

- Best Uses for Laser Engraving Machines for Metal

- Common Questions About Choosing a Laser Engraving Machine for Metal

- Recommended Beginner Setup for Metal Engraving

- Safety Tips for Using Laser Engraving Machines for Metal

- Conclusion: Choosing the Right Laser Engraving Machine for Metal

Whether you’re planning to start a small metal engraving business, personalize products, or integrate metal marking into your manufacturing process, this guide will help you make an informed, confident purchase.

What Is a Laser Engraving Machine for Metal?

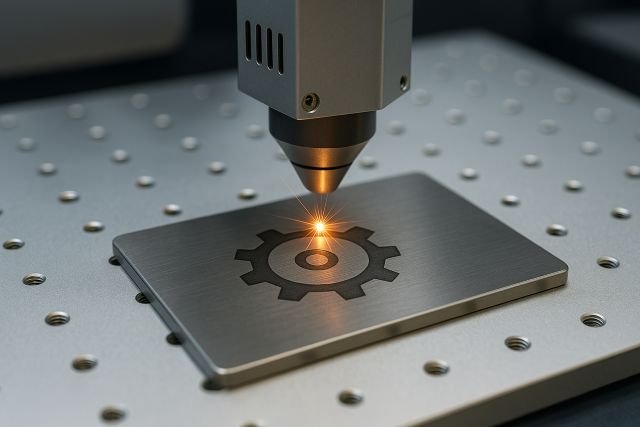

A laser engraving machine for metal uses concentrated laser energy to remove material from the surface, creating permanent markings, patterns, serial numbers, or designs. Unlike surface-only methods like printing, laser engraving alters the top layer of the metal, making the mark resistant to heat, wear, and chemicals.

Most modern metal engraving systems use fiber lasers, known for their precision, speed, and durability. These machines are used across industries like jewelry, automotive, aerospace, manufacturing, and customized gift production because they offer consistent results with minimal maintenance.

Why Use a Laser Engraving Machine for Metal?

Laser engraving is increasingly replacing traditional mechanical methods due to its accuracy and efficiency. Studies show that fiber laser systems can work up to 10× faster than CO₂ and diode lasers on metal, primarily because of their wavelength compatibility with reflective surfaces.

This technology is ideal for:

- Permanent product identification

- Branding and logo engraving

- Tools, tags, and serial number marking

- Custom art, jewelry, and gifts

- Industrial manufacturing workflows

Because lasers are non-contact tools, they prevent material distortion and ensure clean, fine-detail results — even on hard metals like stainless steel or titanium.

Types of Laser Engraving Machines for Metal

Understanding the main types of laser machines is essential before purchasing. Each has unique strengths and limitations, depending on your goals.

1. Fiber Laser Engravers (Best for Most Users)

Fiber lasers are the industry standard for metal engraving. Their 1064 nm wavelength absorbs efficiently into metals, making them ideal for deep engraving and high-speed marking.

Best for: stainless steel, gold, silver, titanium, brass, copper, aluminum, hardened metals.

Why beginners love them:

Fiber lasers offer low maintenance, long lifespan (up to 100,000 hours), and high engraving speed. They also deliver extremely fine detail, which is perfect for jewelry, tools, and industrial labels.

Examples of typical applications include:

- Engraving serial numbers on tools

- Creating CNC identification plates

- Customizing metal jewelry

- Deep-engraved logos for businesses

2. CO₂ Laser Engravers (Not Ideal for Raw Metal)

While CO₂ lasers excel with wood, acrylic, and glass, they struggle to engrave metals without chemical additives or coatings. Their 10,600 nm wavelength cannot be absorbed efficiently by reflective surfaces like aluminum or steel.

CO₂ lasers are only suitable for metal when:

- The metal is anodized

- The surface is painted or powder-coated

- A metal-marking spray is applied

They are NOT recommended for deep engraving on raw metal.

3. Diode Lasers (Entry Level but Limited)

Diode lasers are popular among hobbyists due to affordability. Some claim to engrave metals, but results are limited to surface marking rather than true engraving.

Best use cases: coated metal keychains, painted tags, phone cases.

For users who want professional-grade metal engraving, diode lasers are not sufficient.

How to Choose the Best Laser Engraving Machine for Metal

With dozens of models available, how do beginners choose the right one? Below are the most important factors to consider.

Laser Power: How Much Do You Really Need?

Laser power impacts engraving depth, speed, and the types of metals you can engrave.

20W Fiber Laser:

Great for beginners who need fine marking, text, and light designs.

Not suitable for deep engraving (over 1 mm).

30W Fiber Laser:

Most versatile choice. Great balance of speed and depth.

Ideal for small businesses.

50W Fiber Laser:

High-performance engraving with fast throughput.

Best for deep engraving and industrial use.

100W Fiber Laser:

For advanced users requiring deep cuts in dense materials.

For beginners, 30W fiber lasers offer the best value and versatility.

Working Area Size

Standard fiber laser engravers include field lenses in sizes like 100×100 mm, 200×200 mm, or 300×300 mm.

Smaller lenses offer:

- Higher precision

- Better engraving detail

- Faster speed

Larger lenses offer:

- More working space

- Lower engraving density

Beginners should start with a 100×100 mm or 200×200 mm lens.

Engraving Speed

Fiber lasers typically engrave between 3,000–7,000 mm/s depending on power and software optimization. For production work, speed matters.

A 30W fiber machine provides a good balance of speed and engraving clarity.

Cooling System

Fiber lasers use an air-cooled system, eliminating the need for external chillers. This reduces maintenance costs and simplifies operation.

Software Compatibility

Most machines use:

- EzCad2 or EzCad3

- LightBurn (Galvo version) — beginner-friendly

Look for a machine that includes licensed software and supports standard file formats like SVG, DXF, AI, BMP, and PNG.

Metal Compatibility

Your machine must be capable of engraving the metals you plan to work with. Fiber lasers engrave:

- Stainless steel

- Gold

- Silver

- Titanium

- Aluminum

- Brass

- Copper

- Tungsten

If the metal is reflective, fiber lasers are still the safest and most effective option.

Budget and Pricing

Typical price ranges:

- 20W fiber laser: $600–$1,000

- 30W fiber laser: $1,000–$2,000

- 50W fiber laser: $2,000–$3,500

- High-power models (60W–100W): $4,000–$7,000+

While it may be tempting to buy the cheapest option, beginners often outgrow low-power models quickly.

Best Uses for Laser Engraving Machines for Metal

Laser engraving is extremely versatile. Beginners can start a profitable metal engraving venture with services like:

- Personalized jewelry engraving

- Custom metal card engraving

- Pet tags and industrial plates

- Branded promotional products

- Mechanical part marking

- Nameplates, QR codes, barcodes

Many small businesses earn $50–$200 per engraved item depending on complexity and metal type.

Common Questions About Choosing a Laser Engraving Machine for Metal

Can beginners use a fiber laser safely?

Yes. Fiber lasers are surprisingly beginner-friendly. They require minimal setup, do not need water cooling, and include safety features like emergency-stop buttons and protective goggles.

What metals are hardest to engrave?

Highly reflective metals like copper and polished aluminum require slightly more laser power, but fiber lasers handle them well.

Does laser engraving damage the material?

Engraving removes only microns of material unless you’re doing deep engraving. It does not weaken the structure of most metals.

Can you engrave color on metal?

Yes — color engraving is possible using high-frequency settings on stainless steel and titanium. Results depend on laser power and skill level.

Is a fiber laser worth the investment?

Absolutely. Fiber lasers are long-lasting, efficient, and capable of producing commercial-quality results. Many beginners break even within a few months of selling engraved products.

Recommended Beginner Setup for Metal Engraving

A typical beginner-friendly configuration includes:

- 30W Fiber laser

- 100×100 mm lens

- LightBurn Galvo software

- Rotary axis (for cups, rings, cylindrical objects)

- Fume extraction or good ventilation

This combination offers the best balance of affordability and professional-level capability.

Safety Tips for Using Laser Engraving Machines for Metal

Laser engraving generates fumes and intense light, so you should:

- Wear proper laser safety goggles

- Operate in a ventilated area

- Keep flammable materials away

- Use an enclosure if available

- Follow manufacturer instructions carefully

Reputable brands include safety certifications (FDA, CE, ISO9001), which are essential for long-term reliability.

Conclusion: Choosing the Right Laser Engraving Machine for Metal

Finding the ideal Laser Engraving Machine for Metal as a beginner doesn’t have to be complicated. Focus on the basics — laser type, power, engraving area, software compatibility, and budget. For most users, a 30W fiber laser offers the perfect balance of performance and price. With the right machine, you can engrave everything from jewelry and gifts to industrial components with professional-level precision.

Your investment in the right laser system will open the door to new creative possibilities, a growing side business, or even a full-scale engraving operation. Take your time, compare features, and choose a model that aligns with your long-term goals.