A Sintterikytkin — often translated as a sintered clutch in English — is a specialized mechanical clutch made using powdered metal sintering technology. These clutches are valued for their durability, heat resistance, and excellent friction properties, making them ideal for industrial machinery, power transmission systems, and heavy-duty mechanical equipment.

In the first 100 words, the keyword Sintterikytkin appears naturally to support SEO. This guide explains how a sintterikytkin functions, its advantages, typical use cases, installation insights, and how to choose the right model for your application.

What Is a Sintterikytkin?

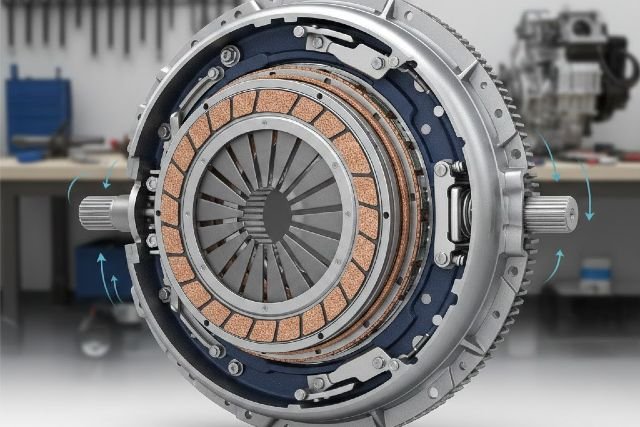

A sintterikytkin is a clutch made from sintered metal components, created through a process where metal powders are compressed and fused at high temperature. This results in a dense, durable structure capable of handling high torque, friction, and temperature variations.

Key Characteristics:

- High wear resistance

- Excellent thermal performance

- Long service life

- Suitable for heavy-duty applications

- Self-lubricating properties (in some materials)

Sintered clutches are typically found in industrial machinery, automotive systems, agricultural equipment, electric motors, and high-precision tools.

How a Sintterikytkin Works

The mechanical operation of a sintterikytkin is based on friction and torque transfer.

Basic Working Principle:

- Torque Input: A driving shaft rotates and engages the clutch surface.

- Friction Contact: The sintered friction material grips the mating surface.

- Torque Transfer: Rotation is transferred to the driven shaft.

- Energy Dissipation: Heat generated is absorbed and dissipated efficiently.

Why Sintered Materials Are Used:

- Stable friction under high load

- Resistance to glazing and fade

- Excellent heat dissipation

- Minimal deformation under pressure

This makes sintered clutches more reliable in demanding mechanical environments compared to organic friction materials.

Types of Sintterikytkin (Sintered Clutches)

| Type | Description | Best Application |

|---|---|---|

| Dry Sintterikytkin | Operates without lubrication | Power tools, electric motors |

| Wet Sintterikytkin | Uses oil for cooling | Automotive transmissions |

| Multi-Plate Sintterikytkin | Multiple friction discs | High-torque machinery |

| Single-Plate Sintterikytkin | One friction surface | Light-duty equipment |

| Centrifugal Sintterikytkin | Engages at specific RPM | Small engines, scooters |

Understanding these variations helps engineers select the best option for durability and performance.

Benefits of Using a Sintterikytkin

Using a sintered clutch offers several technical advantages:

1. Superb Heat Resistance

Sintered metals withstand extremely high temperatures without degrading, making them ideal for constant-use equipment.

2. High Torque Capacity

The density and strength of sintered components allow effective torque transmission under heavy load.

3. Long-Lasting Performance

Due to wear resistance, sintterikytkin offers extended service life compared to organic friction materials.

4. Consistent Friction Coefficient

This ensures reliable and predictable performance, improving safety and efficiency.

5. Low Maintenance Requirements

Some sintered materials are self-lubricating, reducing the need for routine servicing.

Common Applications of Sintterikytkin

Industrial Machinery

Sintered clutches are widely used in:

- Press machines

- Conveyor systems

- Textile machinery

- Packaging lines

Automotive Systems

Common in:

- Wet clutches

- High-performance transmissions

- Racing vehicle components

Agricultural & Forestry Equipment

Used in tractors, harvesters, and PTO-driven machinery.

Electric Motors & Power Tools

Often found in:

- Drills and grinders

- Compressors

- Robotics systems

Small Engine Machines

Such as:

- Scooters

- Chainsaws

- Garden equipment

Sintterikytkin vs. Traditional Clutches: Key Differences

| Feature | Sintterikytkin | Traditional (Organic) Clutch |

|---|---|---|

| Heat Resistance | Excellent | Moderate |

| Durability | High | Lower |

| Torque Capacity | Strong | Depends on material |

| Maintenance | Low | Higher |

| Cost | Slightly higher | Lower upfront |

| Performance | Consistent | Varies with wear |

Conclusion: Although slightly more expensive, a syntterikytkin offers superior long-term value.

How to Choose the Right Sintterikytkin (Buying Guide)

1. Determine Torque Requirements

Higher torque applications require multi-plate or heavy-duty sintered materials.

2. Consider Operating Environment

Examples:

- Heat-intensive tools → dry sintered clutch

- Oil-based systems → wet sintered clutch

3. Check Rotational Speed (RPM) Compatibility

Ensure engagement is smooth and safe at intended speeds.

4. Material Composition

Common materials include:

- Copper-based sintered metals

- Iron-based powder metals

- Bronze composites

5. Verify Manufacturer Quality Standards

Look for:

- ISO certification

- OEM specifications

- Heat treatment tests

- Material density reports

Installation Guide: How to Install a Sintterikytkin Safely

General Installation Steps:

- Disconnect power and secure machinery.

- Clean the mating surfaces thoroughly.

- Align the input and output shafts.

- Install the clutch using correct torque values.

- Test engagement at low RPM.

- Run system diagnostics for noise and vibration.

Safety Tips:

- Always consult the manufacturer’s instructions.

- Use precision tools for alignment.

- Ensure adequate cooling or lubrication system.

Maintenance & Troubleshooting Tips

Although sintterikytkin requires minimal maintenance, monitoring improves lifespan.

Maintenance Checklist:

- Inspect for wear patterns

- Check temperature during heavy operation

- Clean dust or debris

- Verify lubrication (for wet clutches)

- Perform periodic torque testing

Common Issues & Fixes:

| Problem | Possible Cause | Solution |

|---|---|---|

| Slipping | Glazing or wear | Replace clutch plate |

| Overheating | Misalignment | Realign shafts |

| Noise | Incorrect lubrication | Add or adjust oil |

| Delayed Engagement | Worn springs | Replace components |

Frequently Asked Questions (FAQ)

1. What is a sintterikytkin?

A clutch made from sintered metal designed for high-performance applications with excellent friction and heat resistance.

2. Is a sintterikytkin better than a regular clutch?

Yes, for heavy-duty or high-temperature work, it performs significantly better.

3. How long does a sintterikytkin last?

Depending on usage, often 2–5× longer than standard clutch materials.

4. Can I install a sintterikytkin myself?

Experienced technicians can, but precision alignment and correct torque values are essential.

5. Where is a sintterikytkin used?

In industrial machinery, automotive systems, robotics, power tools, and agricultural machines.

Conclusion: Why a Sintterikytkin Is the Ideal Choice for Modern Machinery

A Sintterikytkin provides exceptional durability, thermal efficiency, and torque performance, making it an essential component for demanding mechanical systems. Whether you’re working with industrial equipment, power tools, or automotive machinery, choosing a sintered clutch ensures long-term reliability, reduced maintenance, and enhanced operational efficiency.

By understanding its function, benefits, and correct usage, you can make informed decisions that improve safety, productivity, and cost-efficiency.